The Mikoyan-Gurevich MiG-7 was a World War II era, Russian, fighter. Its fuselage was similar to the more popular MiG-1 and MiG-3. However, its wing was made much larger to fulfill its role as a high altitude interceptor. This increased wing area makes it an ideal subject for 1/12 scale combat. This model airplane plans outline is true to 1/12 scale with the exception that the wing has been enlarged by 5%, further improving its flying characteristics. This makes it legal for both the 2105 and 2610 classes of RCCA combat. Corrugated plastic, known by the trade name Coroplast®, is the primary construction material. While not indestructible, this does produce a tough airplane that will withstand all but the most brutal mid-airs and crashes. In addition the material is extremely inexpensive and lends itself to fast assembly. These characteristics make this model airplane plans a distinct and unusual in nature.

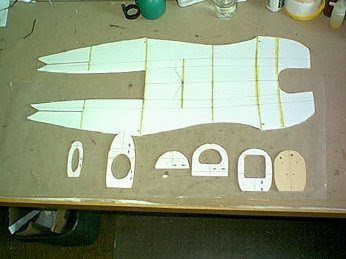

PLANS AND TEMPLATES for Model Airplane Plans:

PLANS AND TEMPLATES for Model Airplane Plans:This type of model airplane plan is built differently from most Radio Controlled model airplane plans designs; and as such has unconventional model airplane plans. Instead of views that you build the model over, there are a series of templates that you cut out and trace onto the plastic. The plans consist of three “D” size (22 X 34) sheets. A “.dxf” file is provided for those with CAD systems and access to large format plotters. Three JPEG image files are given above, click them to enlarge and download to your computer; these are three full-size plan drawing sheets. You can print these at reduced (letter) size as a guide to the larger rc model airplane plans, send them to a large format printer or print small and enlarge. The airplane plans are also available as tiled “.pdf” files for each sheet. Each sheet is divided into eight letter sized (8 ½ X 11) pages. You can print them out and tape the pages together to make the model airplane plans. It’s more work, but it’s cheap! Whatever method you use, take care that the printer, plotter, or copier does not distort or incorrectly size the airplane plan. Each sheet has a 6-inch scale drawn on it – check it with a ruler.

MATERIALS AND GLUES for RC Model Airplane Plans:

Coroplast® is inexpensive (about $7.50 for an 4 X 8 foot sheet) but can be a little hard to find. Try local sign supply shops, artist supply stores, or industrial supply houses. On the web: coroplast . com has more information and numbers to call for local resellers; cadillacplastic . com is a large distributor. You will need a 2 X 3 ft. piece of 2mm material for the wings and a 20 X 30 inch piece of 4mm material for the fuse and tail. With careful planning you can build six planes from one 4 X 8 foot sheet of each thickness. You can buy green Coroplast for the common MiG-7 scheme or white for the Russian winter paint scheme. If you have the 4 X 8 sheets cut to 2 X 4 for UPS shipping, make sure the corrugation pipes (or “flutes”) run the LONG (4 ft) dimension. Most glues don’t stick very well to Coroplast®, so if you anything use other than the suggested glues, make sure to test them first. I use Dap Weldwood® Contact cement for most of the assembly – spread it on each surface, wait 15 minutes (or up to 2 hours), and stick the parts together. “GOOP” or “Shoe Goo” is good for visible areas and those that need a little filling. Polyurethane glue (like Elmer’s

“Probond”) is used for strength in the wing joiners and the firewall. This glue requires moisture to activate and expands as it sets.

CONSTRUCTION of R/C Model Airplane Plans- MIG-7

Starting with the 4mm parts on sheet 3, cut the templates from the model airplane plans. Arrange the templates on the 4mm Coroplast sheet making sure that the pipe directions are as indicated. Temporarily tape the templates down and trace their outline with a fine point permanent marker. Use a pin to mark the intersections of internal lines and connect the marks after removing the templates. Make sure to make a second copy of the Aileron and Saddle Doubler parts. Cut out the Fin and Stabilizer parts using a sharp X-acto knife. Glue a stop onto a #11 knife blade so that the point will only penetrate through the top surface of the Coroplast. Use this to slice away the bottom of a corrugation pipe at the stabilizer hinge line, leaving the top surface in tact to act as a hinge. Glue the Fin to the Stabilizer with GOOP, making sure that the tab on the fin fits fully into the slot in the stab. Set the assembly up on small boxes or blocks to insure that the parts are perpendicular, and allow drying.

FUSELAGE - RC Model Airplane Plans- MIG7

Use the special knife, described above, to cut through the surface of each pipe in the indicated areas of the fuselage. Make sure you do not cut all the way through. I usually make these cuts, with the aid of a straight edge, before cutting the fuselage outline from the sheet. Cut out the fuselage outline. You can use a standard hole-punch to make the ¼” holes for the wing hold down dowels. Cut the fuselage former templates from sheet 1 of the plans and glue them onto wood with rubber cement or 3M 77. The Firewall is 3/16 hard plywood. F5A and F5B are stiff 1/16 balsa. The other formers can be 1/8 light ply or two laminated sheets of 1/16 balsa glued with the grain at 90 degrees. The latter is lighter and stronger, but takes a little longer to make. After cutting out the wood, you can leave the paper in place or remove it. If you do remove the plan paper, make sure to mark the vertical center lines for alignment later. Glue F5A and F5B to the top of F5, as indicated on the plans. Drill holes in the firewall for the engine mount, throttle linkage, and fuel lines.

Test fit the formers into the fuselage plastic making sure that the plastic curves smoothly over the formers’ curves. Now, lay the fuse flat and apply contact cement along all the former alignment lines. Spread the cement at least ¼ inch wide to allow for minor misalignment. Apply contact cement to the formers. I use a small squeeze bottle to apply the glue to the former edges. Let the glue dry for at least 15 minutes. Then, stick the firewall and F2 to the centerline and carefully pull the plastic part way around them. Add F3 and F5, again making sure the centerline mark on the formers aligns with the centerline of the plastic. Continue pulling the fuse sides up and into contact with the formers. Insert F4 and F6 to complete the fold up. Wrap masking tape around the firewall, F2 and F5 to pull the plastic tight against the formers. Install ¼ hardwood wing hold down dowels. Glue these securely to F2 and F5. We will return to the fuselage of model airplane plans of MIG-7 after the wing assembly.

2MM PARTS of MIG-7 (RC model airplane plans)

Cut out the templates on sheet 2 of the plans. Arrange, trace, and cut out the 2mm parts. Be sure to make a LEFT and a RIGHT wing by flipping the template over (print side down). Again transfer the guide lines and fold lines onto the plastic. And again, make sure the pipes are orientated as indicated. The fold line on the wings runs perpendicular to the pipes. Crease (but do not cut) the line with a pointy but blunt object (like a Philips head screwdriver). Another tool that works well is the roller used for repairing screens. Use a straight edge to insure the crease line is straight. Fold the wing over a table top edge, then all the way over. Using the same tool make creases in the Nose Doublers and the Wing Bottom Doubler. For the Firewall Doubler and the Aft Top part run the creasing tool along each and every pipe to ease bending.

WING ASSEMBLY of MIG-7 (Model Airplane Plans)

Cut the Ailerons where shown and create hinges on the outer sections using the same method as the elevator. Note that the moving part of the aileron does not extend all the way into the fuselage. Cut the wing spars form a yardstick or other suitable material. Using contact cement, glue the spar to the line on the bottom of the wing. Don’t glue the tapered tip of the spar down yet – let the wing lay flat. Also, glue the aileron to the bottom of the wing overlapping up to the hinge line. Now, apply contact cement to the top of the spar, the top of the in-wing part of the aileron piece, and all around the outer edge of the wing. Apply a nice ½ to ¾ inch wide band. When the glue is ready, the critical folding begins! While holding the wing bottom flat on your workbench, fold the top over. Start at the wing root and work toward the tip. Try keeping the leading edge held down against the table. Press the wing top against the spar; from root to tip. Then press down the trailing edge; again root to tip. Finally press the wing tips against the spar and squeeze them together. If you did a good job of holding the leading edge down against the table, you should have a nice airfoil with a slight under camber toward the trailing edge, and a few degrees of washout at the tip. Repeat the process for the other wing panel. Trim off any overhang at the tips and trailing edge. Make sure that the ailerons move freely. It is easiest to install the torque rods before joining the wing panels. Refer to the detail on sheet 1 of the plans. I use a 4-40 pushrod, (which is about 3/32 in diameter with 4-40 threads on one end). Since the rod would be too loose in the corrugation by itself, make a bearing out of hard balsa. 1/8 X 3/16 balsa fits snugly into the corrugation. Drill a 3/32 hole in a piece 1 ½ to 2 inches long and glue in place. Cut a hole in the top wing surface about ½ inch from the edge for the torque rod exit. Bend the threaded end at a right angle and slide the rod into the bearing. Create a notch (about ¼ “ deep) in the edge of the aileron by removing the inner webbing. Bend the outer end of the torque rod and cut off the excess. Glue the rod into the aileron notch with GOOP, and tape around the edge with packing tape. Cut out the three dihedral braces, shown on sheet 1, from 1/8 plywood (not lite ply).

Add scrap balsa fillers to the ends of the mid brace as shown in the drawing. Since the spars come together at an angle these fillers make for a better fit. Check the fit of the wing panels with the braces in place – trim as needed for a good fit. The mid brace goes against the front of the spar. Slide the aft brace back to where it is slightly snug in the wing without creating a bulge. The forward brace goes as close to the leading edge as possible. Using polyurethane glue, moisten the edges of the braces and glue into one of the wing panels. Make sure that the braces extend from the panel at right angles to the wing centerline. When the glue is dry, moisten the extending braces edges and the mating edge of the wing, and glue the wing together with polyurethane glue. Prop up the wing tips until the glue dries.

Make a servo cutout in the top of the wing, at the center-line and just forward of the aft brace. Glue small pieces of ply or hard wood to hold the servo screws. Trim about 1/8 inch off the center leading edge of the wing, forming a flat area to better fit the fuselage. Lay the wing into the fuse and trim the trailing edge center area for a good fit. Using contact cement glue the 2mm Wing Center Doublers to the top and bottom of the wing center line. To prevent rubber bands from crushing the trailing edge, glue 1/8 X 3/16 balsa pieces into the wing trailing edge corrugations in the area of rubber band contact.

FUSELAGE COMPLETION MIG-7 (Model Airplane Plans)

Glue the 2mm Firewall Doubler immediately behind the firewall using contact cement. After moistening the area, run a bead of polyurethane glue around the firewall-fuselage joint, forming a glue filet around the front and back of the firewall. Install the Aft Top fuselage piece. Use contact cement to attach the part to F5A and F6 and GOOP where the part attaches to the fuselage. I like to add ½“ wide strips of 2mm material to the inside of the joint between the formers for strength and a smoother appearance. Trim the wing saddle area for a good wing fit. With the wing installed, test fit the stabilizer and fin assembly of the model airplane plans. Make sure the tail is straight with the wing.

The stab leading edge should be tight against F6. Remove the wing and glue the tail in place using GOOP. Push the aft top fuselage up against the fin for a good smooth fit. Before attaching the fuselage Aft Bottom section, install the elevator horn and pushrod. Drilling a hole through the fuse at F6 allows a completely straight pushrod installation. Before installing the control horn onto the elevator, push a couple of short pieces of balsa into the corrugation pipes to avoid crushing by the horn screws. Now, glue the Aft Bottom onto the fuse with GOOP. The Forward Bottom fuselage section is next. Use GOOP and securely tape the nose section inward until the glue dries. The Nose Doublers are attached to the inside of the engine area with contact cement. Bend the doublers inward as you install them to give the fuselage nose a more rounded appearance.

Trim the plastic around the engine compartment to fit your engine. Use contact cement to glue in the Wing Saddle Doublers. Trim them to the same profile as the fuse sides to provide a close fit for the wing. Since the plastic wing tends to slide around easily in the saddle, I usually apply Silicone Sealer (RTV) to the saddle. Simply tape plastic wrap to the wing, apply a nice bead of RTV to the wing saddle, attach the wing with a few rubber bands, and let dry overnight.

FINAL ASSEMBLY of the MIG-7 (Model Airplane)

Use packing tape (or covering trim strips of the appropriate color) to cover the open pipes along the leading edge of the stab and fin. Also cover the seams along the aft top fuse and fuse bottom pieces – to give the plane a finished look. Tape the edges of the nose area to keep fuel out. Then, coat the engine compartment with a thin coat of epoxy to fuel proof everything. The canopy is an off-the-shelf 11-inch WWII design (Sig Manufacturing Co. #SIGWC811). Cut it down to 6.75” as shown on the plans. Paint it as desired and glue in place using GOOP. The front of the canopy is 3 5/8” forward of F5, the back is 3 1/8” aft of F5. Install the servo tray between F3 and F4. The holes shown are sized for Hitec HS-80 servos – adjust them as needed for your servos. Glue scrap balsa rails to the formers to support the tray, and add hard wood strips for the servo screws. Install the engine and throttle linkage. The hole in F2 is sized for a Hayes 6 oz fuel tank. Wrap the battery and receiver in foam and install behind and beside the tank (or where needed for proper balance). The center of gravity (CG) is 3 ¼” back from the leading edge of the wing – measured where the wing meets the fuselage. Set the control throw on the elevator to about 3/8” in each direction. Set the ailerons to about 3/8” each way too. Measure the throws at the widest part of the control surface. If the elevator or aileron hinges are too stiff for smooth, twist free operation, cut ½” slots every inch or so down the hinge center-line.

FLYING of MIG-7 (Radio Controlled Model Airplane Plans Execution)

Have someone launch the plane for you for its first flight. Once you have the plane trimmed, it is easy to self launch. I grab hold of the aft wing dowel from under the fuse and use an overhand throw. I’m sure that you will enjoy the MiG-7 made through given rc model airplane plans. It is the best flying scale combat plane I’ve flown so far. So, go out and cut a few streamers. Just be safe and Happy Flying!

Copyright Note: This plan is developed by David West. Feel free to construct models from these plans and distribute the plans to others. However, commercial rights are reserved. You may not sell the plans, or models made from the model airplane plans, without permission from the copyright holder.

Your comments are always welcome.

Zane